Your 1993 Dodge Stealth is one of 6351 that received VIN numbers. Based on the order of the serial numbers, your car was the 5212nd out of the 6351 that were made that year.

Your car was built in the 3rd week of February 1993. Of the 47380 vehicles made at the Nayoga plant, your car was the 40537th vehicle to be created that year.

There are 281 other cars that were made with both the same interior and exterior color. There are 779 cars with the same exterior color and 2316 cars with the same interior color.

Note: The production order is assigned based on the order of the serial number.

it would be very simple...

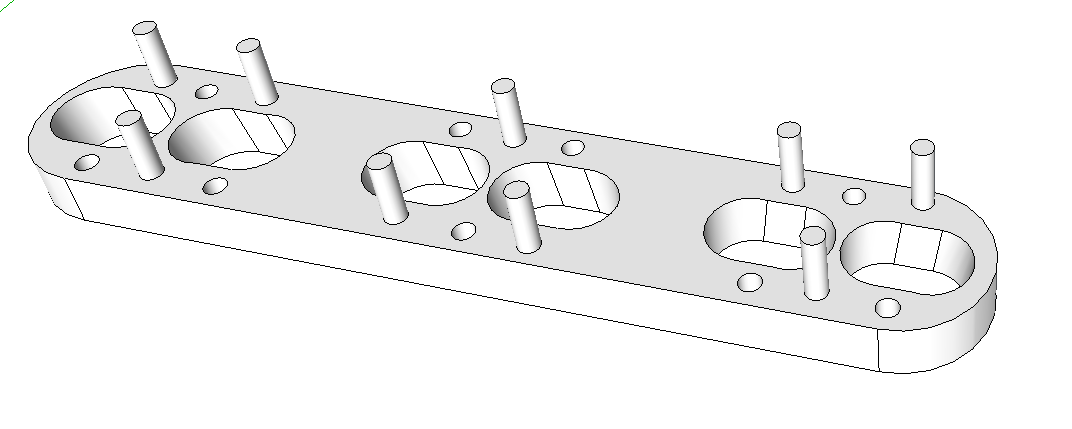

Here's the issue I need to sort out tarzan. The 6G73 plenum needs to do 3 things: Clear the distributor, clear the hood, and bolt on to the LIM on the SOHC.

The 6G73 plenum has the exact same mounting points as the 6G72 DOHC plenum, I don't have that issue if I had a DOHC car. If you see the first page of posts, I need the 6G72/3 ports to taper in to the SOHC ports on the LIM. And since the mounting points on the SOHC LIM and the DOHC LIM are different, the adapter plate needs to bolt down to the SOHC LIM then the plenum can bolt down on the adapter plate. The adapter plate needs to bring the plenum up about 1-1.5 inches to allow the 6G73 plenum to clear the distributor cap.

If I am understanding this correctly the problems the adapter has to accommodate are

1. The ports do not line up flush

2. The mounting locations of the lower intake does not line up with the 2.5l plenum

To accomplish this; first the adapter is going to have to have tapered ports so that the flow from the lower intake to the plenum is flush.

Second the adapter is going have to mount to the lower intake and the mounting bolts will sit flush on top of the adapter so that the plenum can mount to it. I suggest doing this by using flat head socket cap bolts and counter sinking the holes 45 degree so that they will sit flush and with a bit of RTV around the cap will be 100% sealed before the gasket even goes on.

Third the adapter plate will have to be drilled and tapped for the mounting of the upper intake. Since the upper intake is a bit heavy use some thicker studs. To make it easier to service when the time comes make sure you get studs that have a allen socket in the top or a hex head. You could also use press in studs and press them in from the bottom side of the adapter. That would be the strongest way to do it.

Forth you need to get a set of calipers and start taking measurements on the ports of the lower intake and the upper intake so that we I can start making a CAD design that can be transferred right to a CNC mill and set loose.

It's even easier if I use the SOHC and the DOHC gaskets and lay them on a sheet of plywood and cut it and match it with plywood then take the model to a CNC mill and have it cut.

That's not even going to be close to accurate enough if you want to all to fit together like OEM. You need precision measuring tools if you want to provide something a machinist can use. I'm sorry but if I bring a piece of ply wood into work I will get laughed at. I'm also not sure how we are going to cut the tapered hole, usually that stuff is cast from a dye. It might even have to be done on a older mill at work where you can set the angle of the head. You are gonna need a good print with a section view etc.

Last edited by Amphiron; 07-14-2012 at 05:14 PM.

here is a quick 10min mock up i did in sketch up, i would have used a better cad program but I don't have any dimensions and sketchup is good for doing guess work, which is what this is.

We don't have a ball mill lol. I was thinking about using our Cincinnati horizontal boring mill. I think if I used the right diameter cutter and then rotated the table to the correct angle and cut one side of each port, tilted the table to the to the other dimension cut the other sides of the port and then mill out the centers that would leave me with the correct taper. With the taper like that I don't think its going to be easily zipped out on a 3 axis CNC mill, you would need a 5 axis for something like this.

|

3000gt.com 3000GT / Stealth International WWWboard Archive Jim's (RED3KGT) Reststop |

|

Team 3S 3000GT / Stealth / GTO Information daveblack.net |

|

Michigan 3S MInnesota 3S Wisconsin 3S Iowa, Nebraska, Kansas 3S |

North California 3000GT/Stealth United Society of 3S Owners 3000GT/Stealth/GTO Forums 3000GT/Stealth International |

|

3S National Gathering East Coast Gathering Upper Mid-West Gathering Blue Ridge Gathering |

Bookmarks