Post Intercooler Injection(3)

Post intercooler injection technically refers to injection anywhere after the intercooler. However, in this discussion we are specifically taking about post intercooler injection which takes place directly after the air-to-air intercooler on an application which has a considerably lengthy discharge tubes

Here the user has numerous locations and plenty of space available to inject after the intercooler. Often times users will believe by placing the nozzle further away from the intake of the engine, they will have better atomization, better charge cooling and ultimately better performance. In a case like the engine above, placing the nozzles directly after the intercoolers is not as desirable as placing them directly inches away front of the throttle body or carburetor, as this is excessively further away then needed.

While this will result in a well atomized, cool air charge entering into the intake manifold. Much of the water methanol injection would have already evaporated leaving little injection available for internal cylinder cooling, added detonation control and reduced EGT's. Additionally, In some case's the air charge can actually begin to heat back up due to excessively long discharge pipes being routed around hot radiator, turbocharger, hot pipes and exhaust.

Location of the mass air meter and IAT or ACT sensor location should always be considered. Never inject pre-mass air. Only in pre-turbocharger applications when done properly can one inject prior to the mass air.

Direct Port Injection

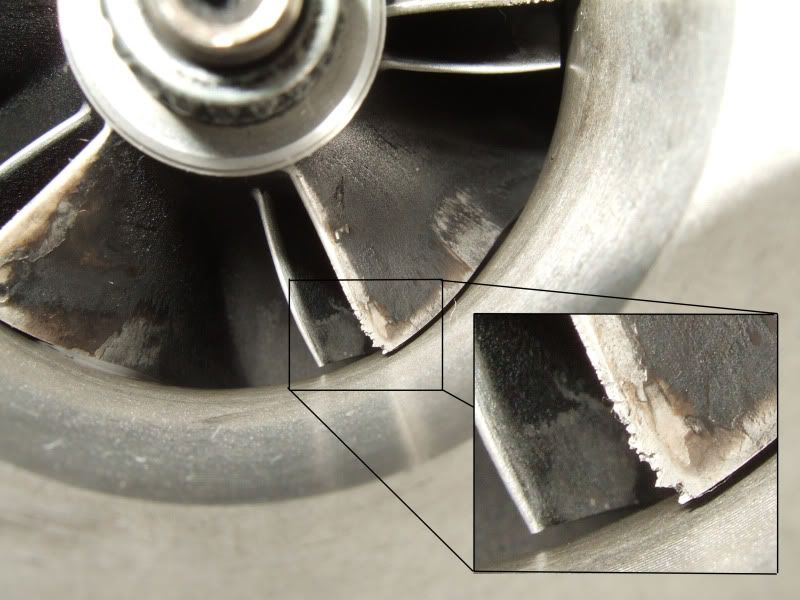

Direct port injection involves positioning a water/methanol injection nozzle in each intake port of the manifold. This allows for the use of several smaller injectors to be used in each intake port as opposed to one larger nozzle located upstream of the intake manifold servicing all the cylinders. Unfortunately, direct port injection generally requires the removal of the intake manifold to complete installation. Thus making for a considerably longer and more complex installation.

While this does offer the benefit of better atomization, more uniform and even distribution through out the cylinders. In addition to possibly better detonation control, cylinder cooling and reduced EGT's. It's generally not needed as other nozzle locations can be nearly just as effective requiring considerably less work and costs involved. Furthermore, one problem with running direct port injection is users are not likely to monitor differences in IAT's (intake air temperatures)

Port injection is more common on 4 cylinder engines as added cost's for additional nozzles and fittings is acceptable and removal of these type of intake manifold is generally much easier. In general, we do not recommend port injection as we have achieved excellent results using other less complicated and costly nozzle arrangements and locations.

Pre-Compressor Injection Precautions

Never place your water methanol injector before the mass air meter. The only time this may be allowed is with pre-compressor injection. When done properly, little or no fluid is exiting the compressor. Only a cooler denser, high humidity air charge with little or no actual fluid remaining in the air charge after the compressor.

When installing your water methanol injection system on a EFI vehicle, it's best to first determine where the IAT or ACT sensor is located before deciding on a nozzle locations. Often times we can position the nozzle before the factory IAT (intake air temperature) or ACT (air charge temperature) sensor location without having to relocate it. This allows us the ability to better use the IAT or ACT sensor for retuning the ECU for the addition of the water methanol injection system.

Unfortunately, many of our newer vehicles have now incorporated the IAT sensor in to the mass air meter. With most applications we can disable this IAT sensor in the mass air meter and install a new separate IAT sensor in a new desirable location.

http://www.alcoholinjectionsystems.c...icle_info.html

Reply With Quote

Reply With Quote

, KWv3, Stedebani suspension buschings, SCE 13'' Stoptech, 2G rear brakes, Forged shortblock, 3SX cam gears, SCE racing oil pan, PST CFDS, RPS 6 puck, RPS Flywheel, ETS FMIC, 3'' custom quad tips catback, new leather seats heated, SCE center diff, Quaife, brand new tranny/tcase, Billet casings, Chrome ECU, Swaintech...

, KWv3, Stedebani suspension buschings, SCE 13'' Stoptech, 2G rear brakes, Forged shortblock, 3SX cam gears, SCE racing oil pan, PST CFDS, RPS 6 puck, RPS Flywheel, ETS FMIC, 3'' custom quad tips catback, new leather seats heated, SCE center diff, Quaife, brand new tranny/tcase, Billet casings, Chrome ECU, Swaintech...

Bookmarks