I used the cx kit last year to try it out. It wasnt perfect but it all fit without any modification for me, and it was only like 600 bucks.

-Austin@STM

-Ricer Evo 8: 8.75 @ 166 Best MPH of 167. Quickest 4G63 Powered Evo in The US!!!

-Chris Cessna's Stock short block Evo 8: 9.76@150 Worlds Fastest Stock Motor Evo 8 and First Stock Block In The 9's!

-Shawna's DD Evo 8: 9.97@143.88 Best MPH of 145 Full leather interior, A/C, navigation, stock brakes, cruisin 9's in style

-Cory's Stock 7 bolt talon: 10.3@136 No crank walk here...

-STM Stock turbo/motor Stealth RT: 10.95@127 Worlds Quyickest/Fastest and most powerful Stock turbo/ motor 3S

-James STM built Pump gas Evo8 stock motor: 10.2@137 Stock long block, and only on pump gas!

-Mike Faggiano Evo3 16g stock motor 1g 11.0@124 just a 16g knockin on 10's door.

And the list goes on...

In all fairness there's almost nothing in your engine bay besides the engine.

there is a shop that will do 3 dollar mandrel bends ten minutes from me. i dont think that will be too bad, but i guess that depends on how many i need and how many times i screw it up. lol. and i thought about the o-ring and the difference in pipe sizing over stock. I figured i would have to do some hack n slash on a extra rear stock pipe, but the more i think about that, the more i think it will look like shit.i think the fabrication part of it is really enjoyable tho, wich is why i thought i would pose the question. hmm, and using exhaust grade steel pipe would be no good due to the rusting, flaking, engine, turbos, bank balance exploding mod. so then you have to spend more just on raw materials, and then try to make it functional and pretty. then buying quality couplers to hold it all together....

What does that mean, how are you going to wire pipes together?

Also steel pipes will rust, ETS used steel piping for a long time, and it rusted on the inside. This caused a lot of issues because they sold it as "stainless" piping, we've had it on a few customer cars here and witnessed the rust first hand. There are threads about it on the Evo and DSM boards. SS or aluminum are the best ways to go.

-Austin@STM

Yes i agree the less couplers the better, less possible problems to run into. However something is wrong if couplers are just popping off.

We run almost 50 lbs of boost in our shop Evo, and it has a standard coupler and t-bolts on aluminum piping on all joints that arent welded, never had a pipe fall off yet.

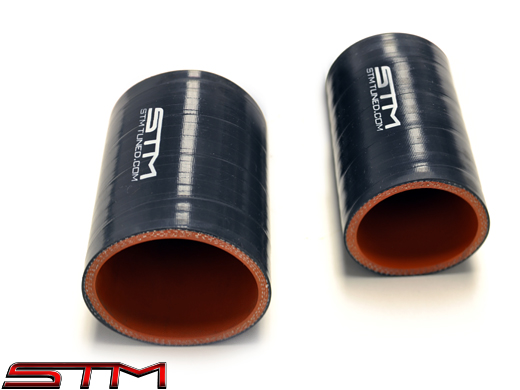

Are you using reinforced multi layer couplers like this? Also do you bead roll your pipes?

A bit off topic......but Just bought the Dejon Y pipe for blow-through, I chose the t clamp option and paid the extra cash for it thinking it was the better option so has anyone get t clamps from them that did not fit? I had these suckers tightened all they down to the end and I was able to pull the pipe right off...

|

3000gt.com 3000GT / Stealth International WWWboard Archive Jim's (RED3KGT) Reststop |

|

Team 3S 3000GT / Stealth / GTO Information daveblack.net |

|

Michigan 3S MInnesota 3S Wisconsin 3S Iowa, Nebraska, Kansas 3S |

North California 3000GT/Stealth United Society of 3S Owners 3000GT/Stealth/GTO Forums 3000GT/Stealth International |

|

3S National Gathering East Coast Gathering Upper Mid-West Gathering Blue Ridge Gathering |

Bookmarks