Originally Posted by

Lithium

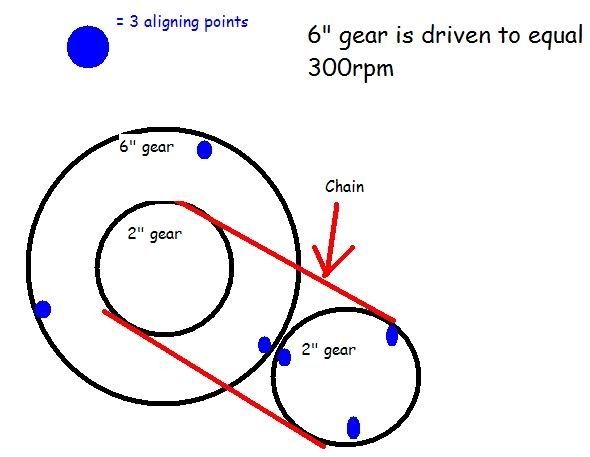

Not entirely, If this machine is using the 6" gear to rotate this assembly then It would give the machine more leverage over the 2" gears. For example if the machine was using an electric motor, an electric motor is limited by its voltage supply. The only way to change that motors output characteristics is to increase/ decrease voltage or increase/ decrease a particular gear set that the motor could be rotating. Long story short, Just like a bicycle, bigger gear in the back allows your feet to have more leverage over the tire but not much speed and vise versa. Small gear in the back allows for more speed but less leverage. So really in his example the size of the 6" gear could be used for regulating the speed of this said rotating assembly.

Reply With Quote

Reply With Quote

Bookmarks