Nice welder dude!

im curious how long you will keep your prices lower than everyone else. if i need turbo work done, as of now, you all are the ones i will go to. but im guessing in a year or so you will be as expensive as dr or any of the other top dogs out there. if you can keep them affordable, then i will not only be impressed, but commend you on your integrity and support of the platform! (not saying anyone else has no integrity or support...)

keep up the good work. i have been and will be keeping a close watch on your guys. looks like a legit deal! and congrats on the success so far. new businesses are crazy, im sure.

rise and rise again until lambs become lions

The back of the compressor wheel on a 9b, 13G, 15G etc are flatbacks meaning they are completely flat. On 13T and 19T's those are superback compressor wheels so they are beveled on the back. I can snap a pic later today and show you the difference, its just how certain turbo wheels are.

Thanks!

Thanks man, we finished the intro pricing on the 19T's so now the prices have gone up to what the website shows the prices at, but even that is only a couple hundred more for the 9b to 19T conversion. That is where the prices will stay unless our vendor raises the prices of our parts which is not likely to happen. I've been a part of the 3S community for almost 6 years now and we are happy to be able to sell turbos at a reasonable price. Other then some of the Garrett turbos we will be selling I dont think we will ever have turbo priced as expensive as some of the other big companies.

Not to say when looking over our budget I wouldn't like to charge more then we are lol. We've spent over 6k dollars in equipment in the last 2 months so it will take awhile to re-coop our costs. But like I've said, we are committed to offering quality turbos at a fair price for the 3S community.

Was the machining of the superback a test of weight reduction? You should get someone to make some billet wheels. I would pay extra, as a later rebuild.

Yeah it was a weight reduction test. I was trying out some different ideas I had.

I've done a little bit of research on the billet wheels, but not much. We are definitely going to look into it more

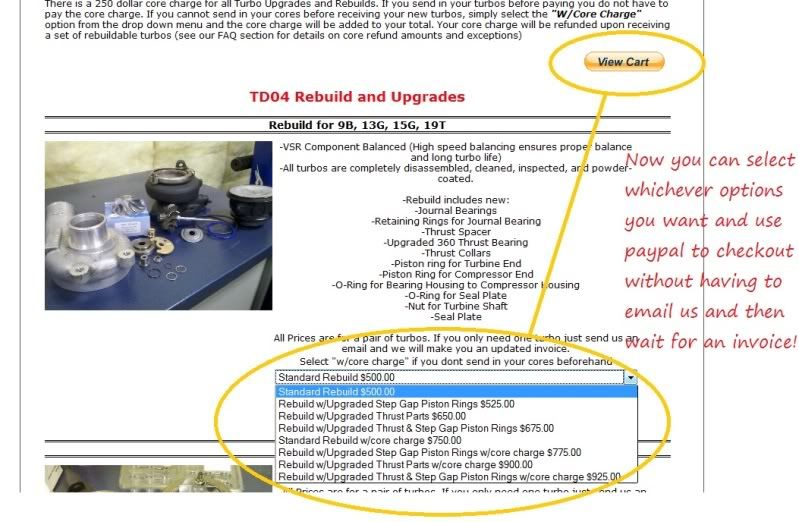

Our website is still a work in progress as we work to update it with more information everyday, but today I got a few of the paypal cart options added to the site. Now you can select which upgrade parts you want, add them to the paypal checkout cart, and then pay for everything at once without having to wait for us to send you a detailed invoice with the upgrade options you want. We still have a couple of the turbo options to finish setting up this way but the 9b, 13G, and 15G are done!

Can you give a description of what all the little extras are in the drop down list? And what came with my turbos(or anyone elses)?

We'd be happy to explain the different options. The 19T's for 900 were our standard rebuild which would be akin to buying a new OEM stock turbo from Mitsubishi. All the parts used (Journal bearings, Thrust parts, piston rings, etc) are OEM quality.

However we know that some people want better then what was offered from the factory, so we offer upgraded parts as well.

Upgraded Thrust Parts

-When used in extreme high performance applications, the original bronze material used in the standard thrust bearing cannot carry the increased axial load. The increased centre point load over the unsupported thrust face can cause the material to flex. In extreme conditions, this flexing can create contact between the thrust faces resulting in immediate failure.

-The material used in the Performance Thrust System is a special steel alloy. The steel has a higher stress limit than bronze and is also a more rigid material, which will deflect less under the same loads.

-The material used for the thrust bearing is a special alloy designed for use in applications requiring high strength and good bearing properties. It has up to 10% porosity making it an ideal bearing surface by absorbing the oil like a sponge.

Increased size of thrust face reducing contact stress

-To enable the thrust system to carry the increased load, the thrust collar and spacer are manufactured to a larger diameter. This spreads the load over a larger area.

-An extra oil feed supply hole to the centre of the bearing helps to increase lubrication to the larger thrust face and also improves cooling.

Note:

These thrust parts must be used as a set and will not work in combination with the standard thrust parts.

Upgraded Step Gap Piston Rings

-Every piston ring even the ones in an engine do not create a 100% perfect seal. However a step gap piston ring helps to create a better seal then a standard piston ring does by the notch and subsequent overlapping created by it.

-For reference every stock turbo from Audi KKK turbos, Garrett, Holset, MHI that we have done has had a standard piston ring. However the inherent design of a standard piston ring will not create a 100% perfect seal where as the step gap will.

Turbine shaft upgrade:

H turbine shaft much larger then the standard TD04 Shaft.

For reference here is a chart with size comparisons.

If you have any more questions regarding any of the upgrades feel free to message us and we can explain more.

I live in MN, could I drop off the cores in person to save on shipping? What city are you guys located in?

|

3000gt.com 3000GT / Stealth International WWWboard Archive Jim's (RED3KGT) Reststop |

|

Team 3S 3000GT / Stealth / GTO Information daveblack.net |

|

Michigan 3S MInnesota 3S Wisconsin 3S Iowa, Nebraska, Kansas 3S |

North California 3000GT/Stealth United Society of 3S Owners 3000GT/Stealth/GTO Forums 3000GT/Stealth International |

|

3S National Gathering East Coast Gathering Upper Mid-West Gathering Blue Ridge Gathering |

Bookmarks