After struggling with the lack of shims for our transmissions for a few years I've finally found a company that sells shims with the right outside diameter.

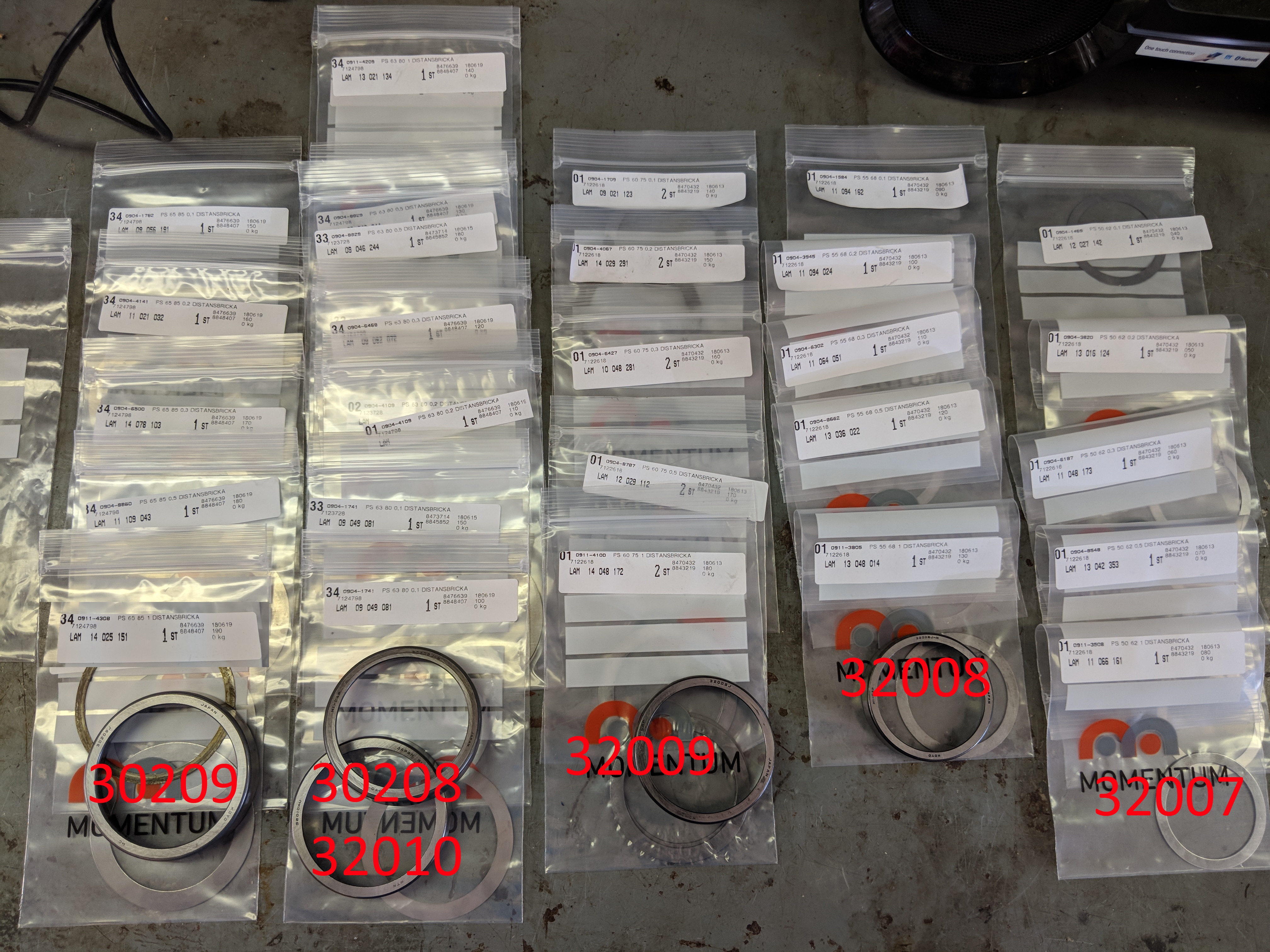

Here is a photo of the shims for our various bearings in 0.1, 0.2, 0.3, 0.5 and 1 mm thickness along with the full part numbers.

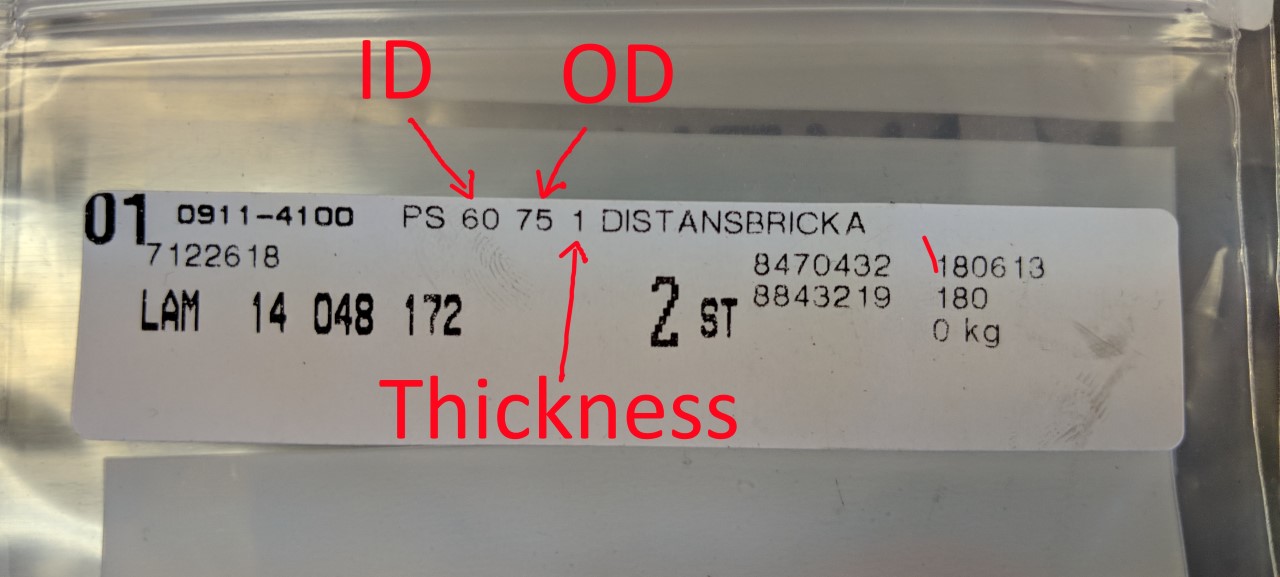

Here a photo showing how to read the labels:

I've purchased the shims from this company:

http://www.momentum-industrial.com

They didn't have them in their standard catalog but after some research they managed to find shims with the correct outside diameter and slightly smaller inside diameter. The shims only cost about 2$ each and they are available in at least 1 mm, 0.5 mm, 0.3 mm, 0.2 mm and 0.1 mm thickness because that's the ones I bought.

I don't know if they sell internationally. If they don't I could probably buy a large set of these and pass them on to a vendor like Chris Hill or Ray Pampena as a workaround.

Reply With Quote

Reply With Quote

Bookmarks