Backstory is, I was shopping for a vehicle to use as a rally support truck. Needed to be AWD, have decent ground clearance, 4 seats, and a decent trunk space. My experience working on BMWs meant I was initially shopping X5's (or a 5 series wagon to build a drift taxi out of, that was plan B), and had passed on quite a few good deals but nothing super great. Was also randomly checking out things like the 4runner, xterra, and pathfinders but wasn't wanting a 4x4. All the reviews I read said the pathfinder rides much better than the 4runner on rough roads and higher speeds, which is exactly what I wanted. Initially didn't look for the QX4 because they were priced higher than I wanted to spend, but it did check all the boxes I wanted. The ATTESA ETS system has a big draw for me though. A random set of events though changed that as an X5 I was going to buy fell through, a local QX4 popped up was sent to me. It was decently clean enough, and more importantly it was a price I couldn't avoid. I went to look at it and verify it had some of the options I wanted it to have, mainly working HID lights, heated seats and rear LSD. The mission was on.

So I bought it. A relatively low mile 2002 QX4 that failed safety inspection due to the front strut towers separating due to rust, it was far enough to be dangerous to drive, as the only thing holding the front left corner up was the brake master cylinder. You could feel the bumps in the road move the pedals. I bought it knowing it needed fixing but figured I'd call Infiniti just to see if they'd fix it for free. Infiniti said the recall inspection was done in 2012, and any damage due to rust since then wasn't their problem. Time to put her on the lift and fire up the welder, bringing her back to life.

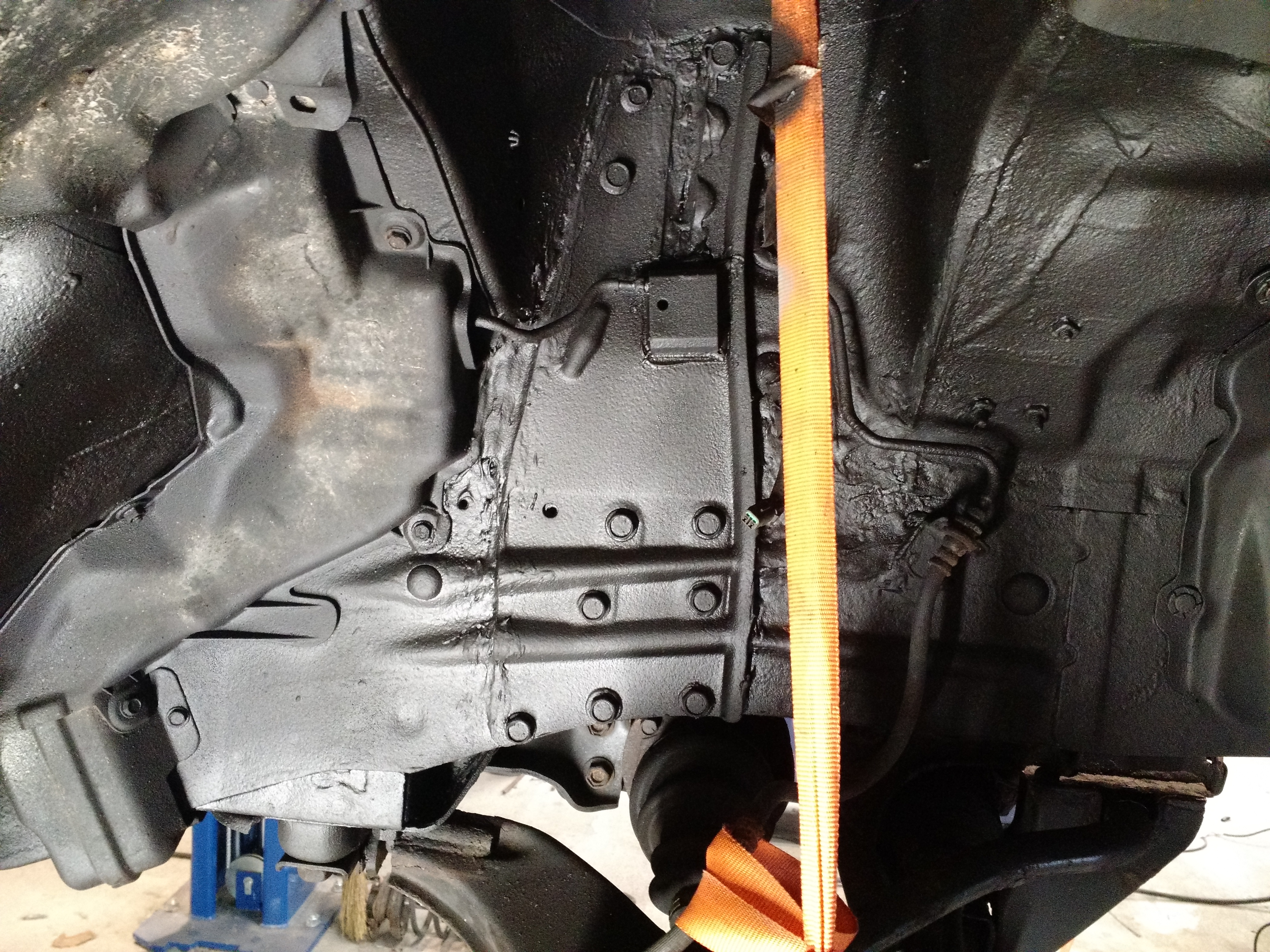

Inspecting the damage, glad to see the mounting points for the repair bracket are in good condition, as I will be using the brackets to position the strut tower in the correct location for the operation. I chose to weld in new metal because I believe the fiberglass repair Nissan came up with is a half-ass way of doing this type of repair.

Driver side:

IMG_20180210_155643909 by Chris Patterson, on Flickr

Passenger side:

IMG_20180210_165932941 by Chris Patterson, on Flickr

The driver's side is even worse than the pic appears, as with the weight of the car on it, the hole is another inch or two taller. Before I took that pic, I had pulled down on the tower some to check how loose it was, and was able to move it a couple inches up and down easily, nothing much was left structure wise. I now can formulate a plan on what I'm going to do. Plan is to clean it up, position the bracket, drill for the bolts, and bolt it in bracket, weld in new metal, remove bracket, finish welding, then install bracket as in the recall so it will be even stronger than when it was new. Oh, and to add to the difficulty, I will also be on a time crunch as I want this completed and back on the road to use for the upcoming Rally in the 100 Acre Wood as a support truck. I had 4 weekends that I could work on it after work, and one or two days a week I can put a couple hours in at night. Also during this time I'll be mounting auxiliary lighting because the factory lights in their current condition just wouldn't work for high speed gravel road use.

Also, in case you're wondering. No, the Montero wasn't on the list of options. They manage to cost more while having less HP and from what I read, not as good an AWD system. The same year Montero has 170ish HP vs this with 240 and room to grow. You know, because I might get bored and turbo it or something...

Reply With Quote

Reply With Quote

)

)

Bookmarks