I just did a re-test of the current TechWorks ECS M03 software in AutoMode and found out that the earlier numbers I quoted about it's performance were not correct... so just to be accurate here's the new numbers:

What I originally said:

--------------------

The TechWorks M03 controller can read the accelerometer every .0094 seconds- rounding up to 0.01 seconds , ie the controller can process about 100 new g force readings every second.

What the new tests show:

----------------------------

The TechWorks M03 controller can read the accelerometer & execute one pass thru the control loop every .0054 seconds (yup it's faster ), which means the controller can actually get 184 new g force readings every second.

Which means this for the summary now:

-------------------------------------------

Techworks controller takes 0.154 secs (not 0.2 secs as originally stated) to detect & complete the transition of struts in a braking situation

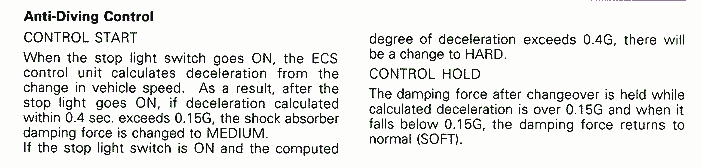

Mitsu controller takes 0.5 secs to detect & complete the transition of the struts in braking situation (according to mitsu specs)

Which means the Techworks controller is over 3 times more responsive than the Mitsu OEM ECS controller in AutoMode for a braking maneuver.

p.s.

I guess I did some loop optimizations in the production code l had forgotten about that weren't in the original test code. For you coding geeks out there - what I did to capture the control loop processing performance was to add somesimple timing & print code to the bottom of the control loop for the testing - it calculates the time in milliseconds to do 10,000 control loop executions:

p.s.s. -fyi when in manual mode & reading the accelerometer is not needed - the time for a single pass thru the main control loop only takes 0.0001 secs (0.1 msecs)

/////////////////////////////////////////////////////////////////////////////////////

//

// main loop

//

/////////////////////////////////////////////////////////////////////////////////////

void loop()

{//

// Check for updates to the state of the Controller Mode

//

myController.readSwitch();

switch(myController.mode()){

case(MANUAL):

if(logMode) doLogMode(LOG_ACCELEROMETER,0,0);

setManualStrutTargets();

setStruts();

break;

case(AUTO):

readAccelerometerValues();

setAccelerometerTargets();

setAutoStrutTargets();

setStruts();

break;

}

//

// display current state of Sport-Tour lights

//

setLoopTourSportLights();

//*************************

// Process loop Timing Calculation

//*************************

if (loopCount ==0 ){

loopStartTime = millis();

loopCount = 1;

}else if (loopCount >= 10000){

// Calculate the elapsed time

loopEndTime = millis();

loopElapsedTime = loopEndTime - loopStartTime;

// Print the Results

Serial.print(F("Elasped Time For 10000 loops= "));

Serial.println(loopElapsedTime);

// Reset the counter

loopCount = 0;

}else loopCount++;

}

Reply With Quote

Reply With Quote

Bookmarks