I finally started installing some parts that I've been accumulating during the past year. This is the first time I've really done anything with a car other than change the oil, change brake pads, and other simple things like that. I have done a few car audio builds but that's a different animal. As such, I will try to show some tricks and useful tools that I've come across (as a newbie) while working on the car.

My brother does body work and paint as a hobby and has gotten rather good, especially when he takes his time, so he will be repainting the outside of the car hopefully this spring.

Now onto the parts lists.

Existing Parts (came with the car):

* K&N FIPK intake filter

* Eibach lowering springs

* TSW Verano 18x8 wheels

* DNP hard intercooler pipes

* ATR exhaust with hi-flow CAT

* Short throw shifter (I was told it was made by OhioSpyderman)

* Adjustable rear control arms

* GReddy Type-S BOV setup for recirculating

* Fuel loop

New Parts:

* Various Mitsubishi OEM weather stripping, bumper brackets, etc.

* oohnoo Dual core FMIC made for DNP hard pipes

* Skillard front bumper splitter

* 1999 Mitsubishi front bumper with necessary brackets (minus the splash shields because I bought the front splitter)

* 3SX Pre-Turbo hard pipes

* New black couplers and T-Bolt clamps (for the DNP hard pipes) from SiliconeIntakes.com

* Stainless Steel, Lined worm gear hose clamps for locations where T-Bolt clamps cannot be used (intake bubble, K&N air filter, etc.)

* Replacement K&N air filter for the FIPK kit (old one was ratty)

* Replacement 3SX adjustable rear control arms (old ones are a PITA to adjust due to corrosion and the heim joints are shot)

* New OEM style radiator hoses

* Aluminum high capacity radiator from 3SX

* Extreme Dimensions 96 Stealth spoiler replica

Still need to purchase:

* Leather seat covers

* TSW Portier 18x9 +30 wheels (if they will fit) or TSW Nurburgrings if the Portiers turn out to be heavy.

* StopTech slotted rotors

Here's what the car looked like before I started tearing it apart.

The DNP pipes, stock radiator, stock SMICs and some other stuff have been removed. I polished the DNP pipes while they are out.

I covered the front splitter with painter's tape to protect the powdercoating while doing mock ups. In addition to the cross-member mounting holes, I drilled holes beneath the radiator support and made a couple 1-3/4" spacers to bolt the splitter up to the radiator mount as well to help support it.

I'm going to go into a bit of detail on my 99 bumper conversion because I wasn't able to find any really good information on what was absolutely 99 specific and what would work from the Stealth. Further more, I couldn't find pictures of just what these brackets looked like.

Here is a picture of all of the brackets that I purchased for the 99 bumper conversion. The 2 large wheel well extensions really aren't needed; the 94 Stealth wheel well extensions will just have an unused mounting hole in each one, as far as I can tell. The sandwich plates are different; the 94 Stealth sandwich plates might be able to be modified to fit but I'm not going to try it since I already have the 99 plates.

This is a side by side comparison of the new 99 wheel well extension and the old 94 stealth wheel well extension. Along the edge that attaches to the bumper cover (located along the bottom edge of each extension in the photo) you will notice 1 less mounting hole in the 99 extension.

Here is a photo of how the wheel well extension brackets fit on the 99 bumper.

The bumper cover to fender brackets from the 94 Stealth also appear to be reusable. I assume that the brackets on a 99 3000GT have a shorter vertical bar with only one mounting hole since the 99 bumper cover doesn't curve up behind the corner lights. The 94 Stealth bracket also does need 1 hole drilled in it to make way for an extra bolt along the horizontal bar. I haven't installed these brackets yet but I don't think the longer vertical bar needs to be cut down.

Here you can see how the vertical bar extends above the bumper cover.

This photo shows the 2 holes in the 94 Stealth horizontal bar lined up with the bumper cover. An additional hole in the middle needs to be drilled in the 94 Stealth bracket. IIRC, the center hole is used to attach the wheel well extension bracket.

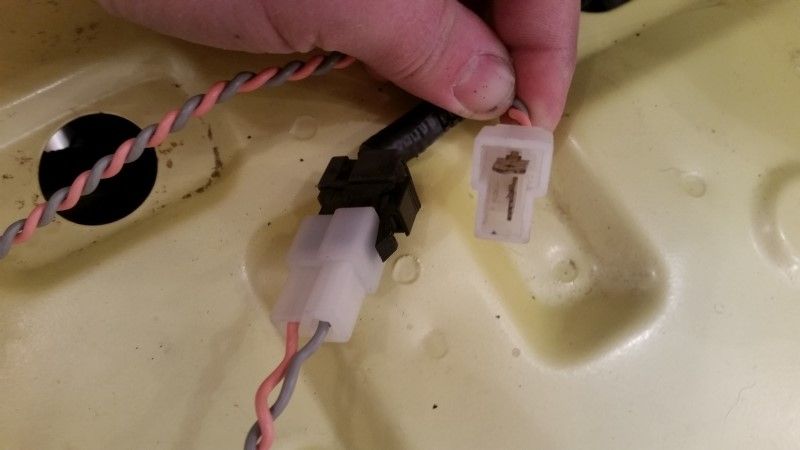

I found this plumbing pipe used to connect a chunk of hose from the BOV to the BOV port on the intake bubble. I'm not a fan of this type of "ingenuity". Also, somebody spent a lot of money for the K&N FIPK and then just folded up the mounting brackets instead of using them which caused the air filter to have a hole worn into the bottom of it. *facepalm* I also found wiring harnesses around the shift linkages that weren't secured in the metal clips. It took all of 3 seconds to place the harnesses in the clips. The positive alternator wire was also loose when I bought the car. It's a lot of stupid, little stuff that just needed another 2 minutes to do right.

I purchased a legitimate 1.25" OD stainless steel joiner to attach the hose from the BOV to the intake bubble. This was $8 from SiliconeIntakes.com. I also purchased a new radiator hose to cut up for the BOV piping.

When I bought the car it had blue vacuum lines that I swapped out for black. It also had corroded/rusty worm gear clamps and silicone hose couplers cut to various lengths with jagged edges so I purchased all new black couplers and T-bolt clamps for the intercooler piping. Since T-Bolt clamps are rather wide and don't always fit well, I also purchased stainless steel worm gear clamps that are lined so that the perforations can't dig into the hoses and cut/scar them. These worked great on the intake bubble.

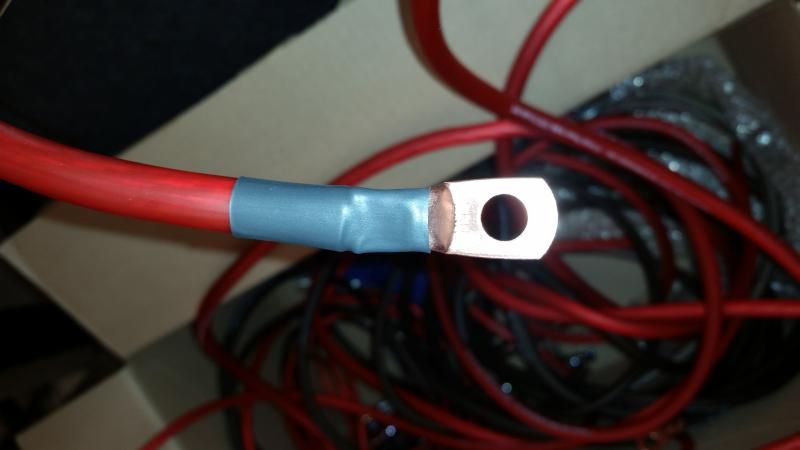

I started to reassemble things; the pre-turbo pipes are in and the Y-pipe is back on. However, this week I decided to go ahead and replace the battery cables. So next on the list is to replace the battery cables and then get back to installing the new radiator, FMIC and intercooler pipes, etc.

I am curious about how people usually attach the Skillard front splitter to the bumper cover. Are people just bolting the bumper cover tight to the splitter, at least on the side sections? Or do I need to purchase the factory splash shields or something?

Reply With Quote

Reply With Quote

I will add to this album if I end up taking more pictures.

I will add to this album if I end up taking more pictures.

Bookmarks