Alright, so I decided to swap my solid aluminum rear diff bushings out for some poly ones.Since no one really sells poly rear diff bushings I decided to make my own like I did for my front control arm. I did not intend to make a write up, so I do not have pictures of actually cutting the stock bushings out. I don't own a press yet, so I just cut the center pins out by hammering a flat head through the rubber. I then used a sawz-all to cut the bushing sleeve out of the mount pieces. After cutting out a groove in the sleeve you should be able to push it out with a flat head and a hammer easily. You will end up with mounts that are like this:

I talked to Pauly P and he pointed me in the right direction for the size of the bushing. It turned out that 9.9484 fits very well. They are 18.99 for a pair, so we will need 2.

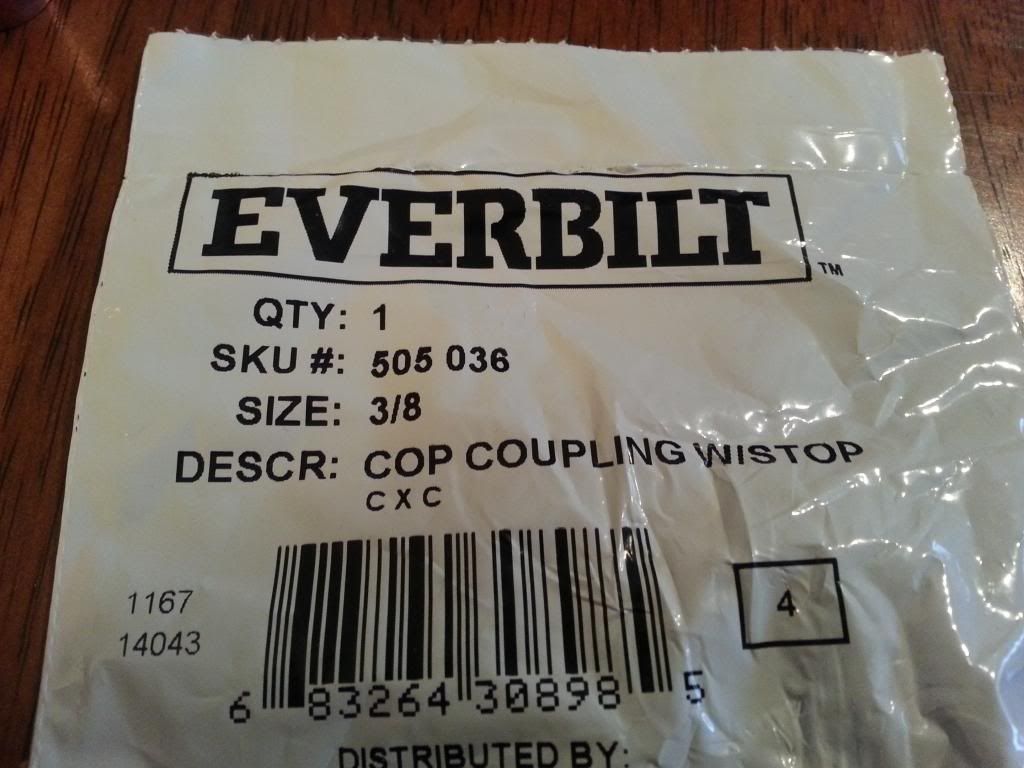

The only problem is the inner diameter on the pins is 9/16" but our bolt is about 3/8" To fix this gap I found some copper pipe couplings (2 per bushing so we need 8 total) at Home Depot at 79 cents each.

I didnt want to risk bending the copper when installing it so i used a spare 17mm bolt to center everything while hammering them in.

They fit very good.

Next, we will need to trim the bushing flange down. For the front 2 bushings I removed about 3/4 of the flange on my bench grinder

and about 1/2 for the rear bushings on the Y plate.

From here the bushings should slide easily into the mount holes. There is a gap between the 2 bushings, but I just fill it with grease and also grease the bushing prior to instillation too.

Here is one of the side mounts mounted to the diff/subframe

Y plate

With shipping, this cost me about $55 when all said and done. After listing up my solid bushings for sale I have received a few pm's asking why I was switching from solid aluminum to poly. I originally had a stock drive shaft with the Aluminum bushings. Surprisingly, the rear drive shaft dampener did a very good job keeping the rear diff quiet with the solid mounts. Shortly after installing the bushings my oem drive shaft u joint on the front yoke decided to go out. Decided to upgrade to a 2-piece aluminum/steel hybrid shaft I found for $450 shipped. Put the drive shaft in and I couldn't stand the whining from the drive train. With poly mounts now the whine is gone. Car feels solid when accelerating and is less harsh DD-ing.

Reply With Quote

Reply With Quote

Bookmarks