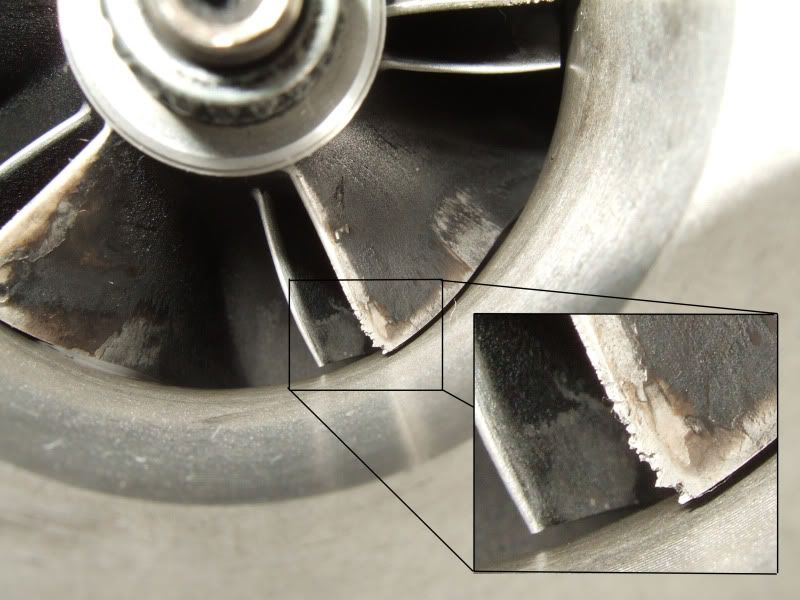

i have done my research on the subject .I find is that almost everyone that has tried have had good results.Still I find that not very many people have tried this and I see why it is precision work and there are great risks involved. I have also found numerous people that have had impeller damage,mostly in these cases they were using large amounts of water and usually had the nossles in a poor location like below.

conclusion :

99% of set up's have zero problems. Your is a combination of bad location, bad shape of intake, non-metal (those rough plastic surfaces grip water droplets) No space for the fluid to properly mix with the airflow (it just settled out of the airstream)

So basically the bad location was like running a stream of water into the blades.

The most correct way to do it is something like:

I believe aquamist makes them .

You can order them here too.

Pre-Compressor Jet Holder - Howerton Engineering, LLC

Bad thing is your limited to one injector per turbo.

The other way to do it would be like this below.This way you could use multiple smaller nozzles to yield better atomisation

And of course, you could weld a bung(s) on the preturbo pipe.

Just make sure the nozzle is long enough to extend far enough inside the nozzle adapter its vital to allow it to spray properly and place it not too far away from the turbo inlet !

Reply With Quote

Reply With Quote

of course

of course

, KWv3, Stedebani suspension buschings, SCE 13'' Stoptech, 2G rear brakes, Forged shortblock, 3SX cam gears, SCE racing oil pan, PST CFDS, RPS 6 puck, RPS Flywheel, ETS FMIC, 3'' custom quad tips catback, new leather seats heated, SCE center diff, Quaife, brand new tranny/tcase, Billet casings, Chrome ECU, Swaintech...

, KWv3, Stedebani suspension buschings, SCE 13'' Stoptech, 2G rear brakes, Forged shortblock, 3SX cam gears, SCE racing oil pan, PST CFDS, RPS 6 puck, RPS Flywheel, ETS FMIC, 3'' custom quad tips catback, new leather seats heated, SCE center diff, Quaife, brand new tranny/tcase, Billet casings, Chrome ECU, Swaintech...

Bookmarks